Let’s lift our game by using science & craft to achieve a dry pit!

Lift pits often leak & lift makers may not Certify the lift – which can stop OC.

Disaster then …. or disaster later – when all the experts in the world fail to waterproof the pit from the inside.

Avoid disasters:

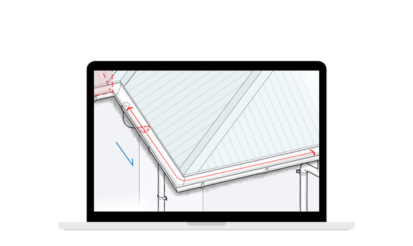

- concrete quality must be verified and on record – get a test for this pour! And ideally from first truck.

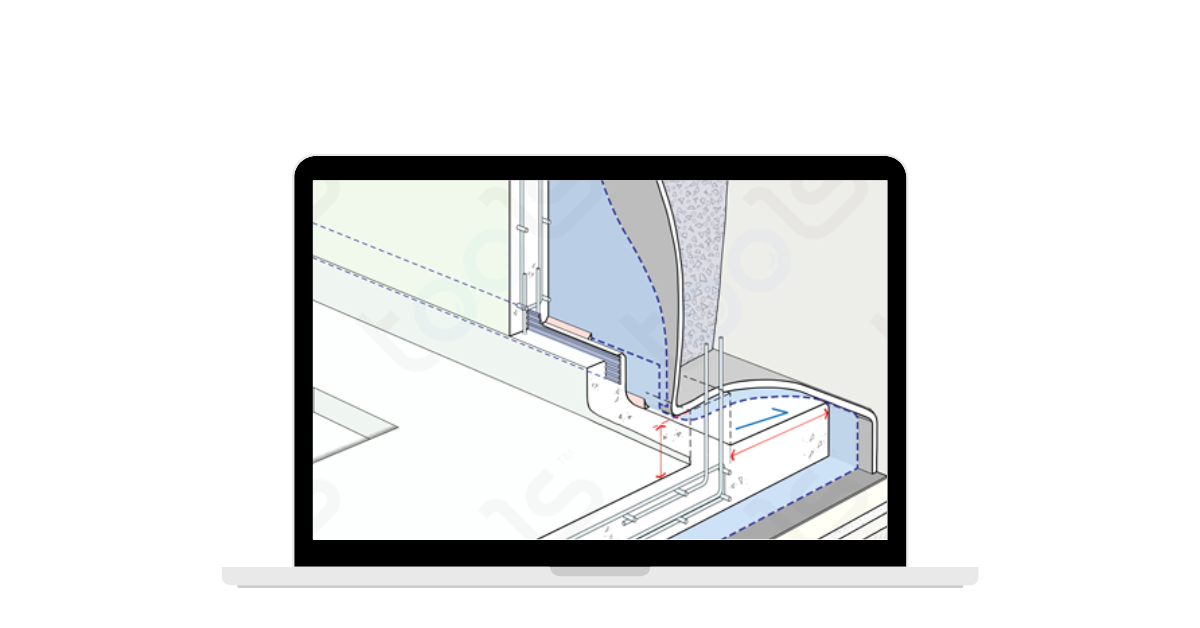

- ensure slab, and especially hob, is very carefully vibrated and, MOST importantly, around the precisely installed waterbar using a needle vibrator

- the indestructible waterbar is key – corners must be fabricated by supplier

- I always slope the pit floor to a small sump – just in case

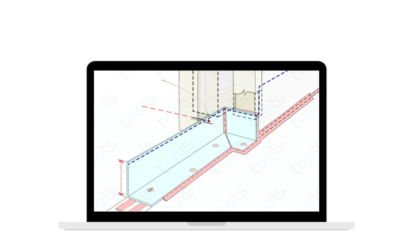

- you will note the 600mm clearance from the excavation – this allows access … yes access so you work effectively on external WPM

- joint between hob and walls above needs a fillet and sealant – and always prime surfaces prior to sealant

- base of membrane must be bonded to a clean concrete surface – I favour into a recess or terminated as approved by supplier

- please invest in a sheet membrane and carefully protect it whilst backfill is being compacted

There is more to talk about ….. which I’ll do in later Tools™

1 min read

1 min read  01 November 2024

01 November 2024