Mastering Metal Cladding: Drainage, Fixings, and Material Compatibility

Metal cladding is durable, stylish, and versatile—but it’s also unforgiving if you don’t get the details right. Our latest Tool™ simplifies the technical rules and ensures that your facades are designed to last.

Precision is Key

Unlike timber or stone, metal can’t be reshaped once installed. That means accurate setout and measurements are crucial. But precision isn’t just about the metal itself—coatings are a science and need to be applied correctly to prevent corrosion and damage.

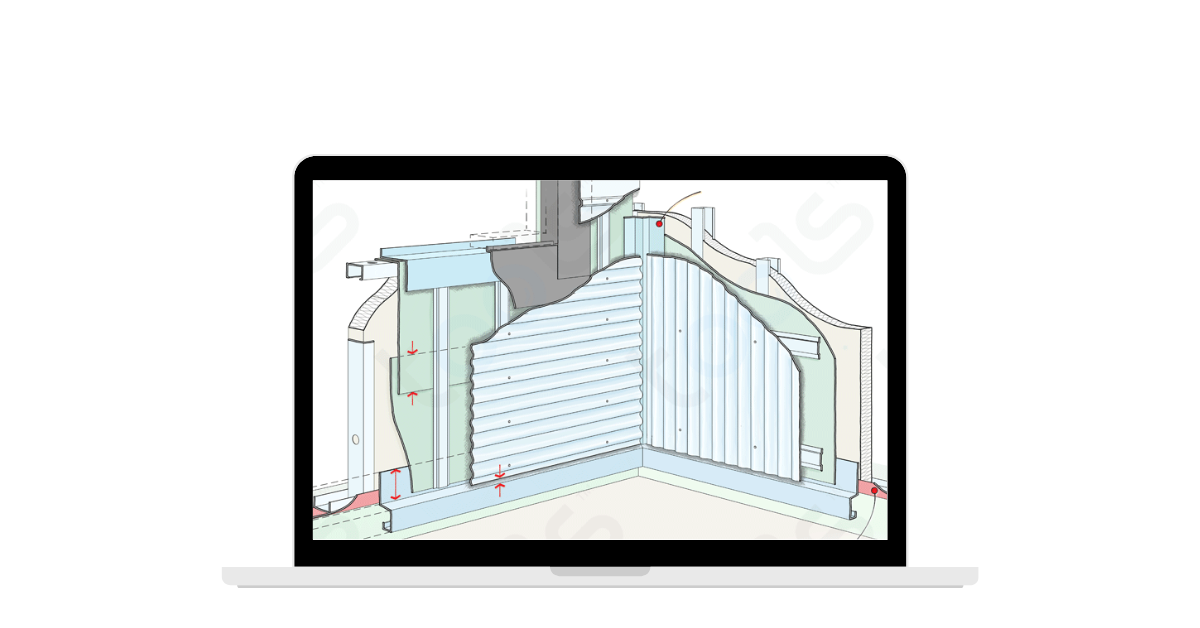

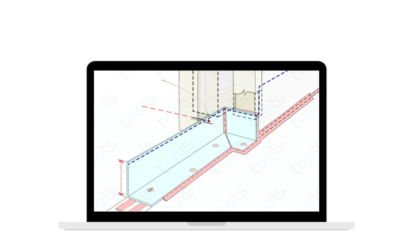

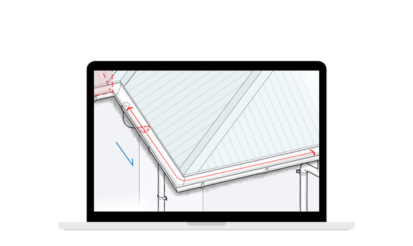

Overlaps, Flashings & Drainage

The biggest mistake? Forgetting that wind pressure can blast water behind joints. That’s why every overlap and flashing must be designed to direct water downhill. A few golden rules:

✔️ Always overlap ‘downhill’ to prevent water ingress.

✔️ Leave a 10mm gap at the bottom of cladding to allow ventilation and self-cleaning of dust and debris.

✔️ Fixings and seals matter—follow manufacturer guidelines to the letter. Class 5 screws are a solid choice.

Material Compatibility: Avoid Costly Mistakes

Metal compatibility isn’t always obvious. For example, Zincalume and lead flashings don’t mix, and stainless steel can corrode Zincalume and Colorbond. Understanding these relationships prevents costly repairs down the line.

Build Smarter with Tools™

With Tools™, you can stop wasting time on complicated compliance research and start using interactive, easy-to-understand graphics that simplify NCC rules.

Explore more insights at Building Tools Blog.

1 min read

1 min read  07 February 2025

07 February 2025