Creating safe access to plant rooms and service areas is crucial. Unlike public stairs, maintenance stairs are compact—so they must be designed with precision to meet both safety and NCC requirements. Our Maintenance Stairs Tool™ simplifies these rules into a single interactive graphic, so you can avoid costly mistakes and build with confidence.

Compact But Compliant

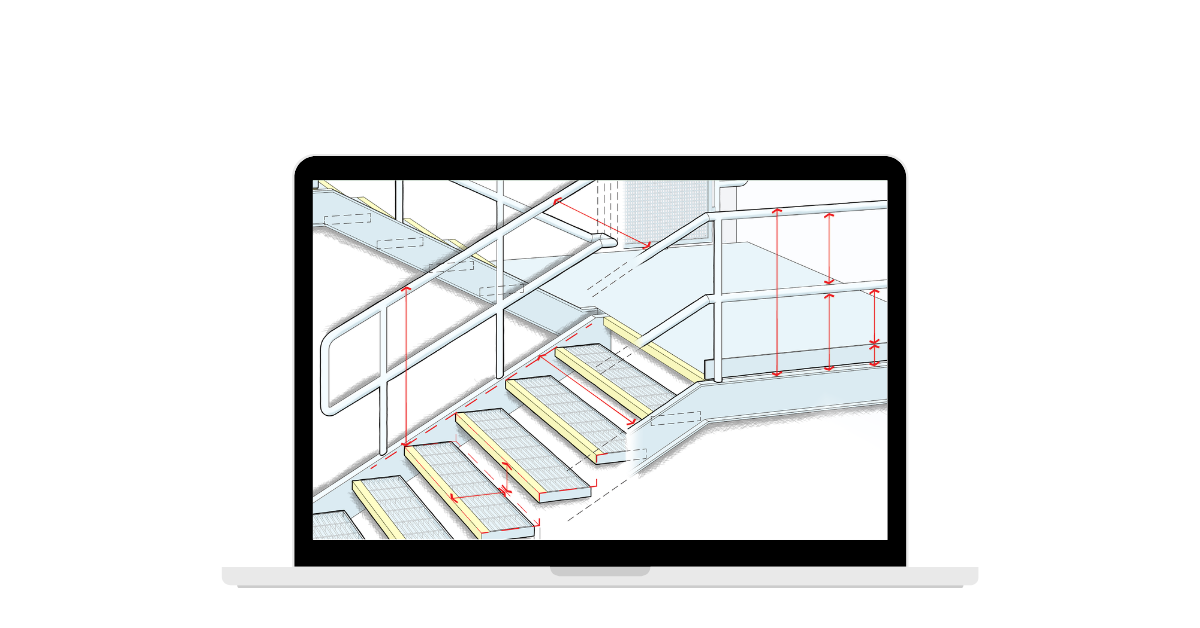

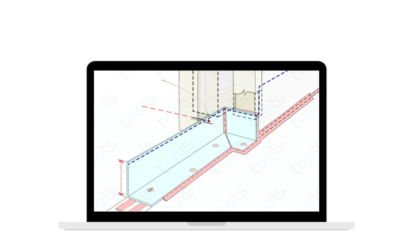

Maintenance stairs must be at least 600 mm wide, with 600 mm landings that remain free of door swings. If there’s no adjacent structure within 10 mm of the landing edge, include a 100 mm toe board to prevent tools or debris from slipping off. In this context, the usual balustrade is known as a guardrail.

Core Stair Rules Still Apply

While the stairs are smaller, standard staircase rules still hold:

- 2 m minimum head height above the pitch line

- Maximum of 18 risers, with consistent riser heights

- Non‑slip treads for secure footing

- Continuous handrails on one side and a centre rail for double‑handed support

Although the NCC allows a 900 mm guardrail, our Tool™ recommends a 1 m minimum to enhance safety around equipment.

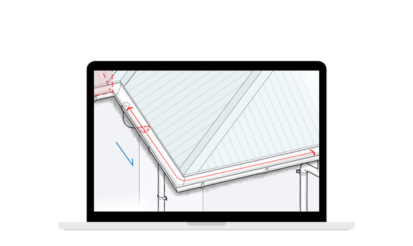

Durable Materials for Long‑Term Use

Maintenance stairs see heavy use and occasional chemical exposure. Choose UV‑resistant, durable materials—aluminium is ideal. Prime site welds carefully to prevent corrosion. And for the best grip and easy maintenance, use 40 mm OD rails.

Streamlined with Tools™

Rather than hunting through code sections, the Maintenance Stairs Tool™ on Tools™ gives you clear, interactive diagrams, NCC references, and best‑practice notes all in one place. It’s the perfect resource to share with your team or include in site briefings.

For broader stair guidance, check out our Stair Compliance Tool™ and Guardrail Best Practices blogs.

2 min read

2 min read  13 September 2024

13 September 2024