Everyone be warned – the base of most steel jambs rust or eventually rust. And we stupidly still specify or install them. This will only change when manufacturers sell us an ‘EVERLAST’ Jamb in etch primed 316 stainless.

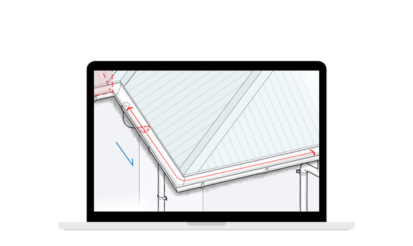

However, whilst we have to use a zincalume or galvanised jamb, let’s do everything to make it work:

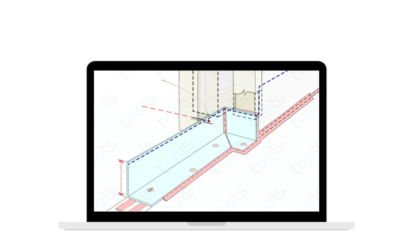

- scribe, cut & metal prime bottom of jambs to suit the different floors level. ⚠️DON’T leave swarf around

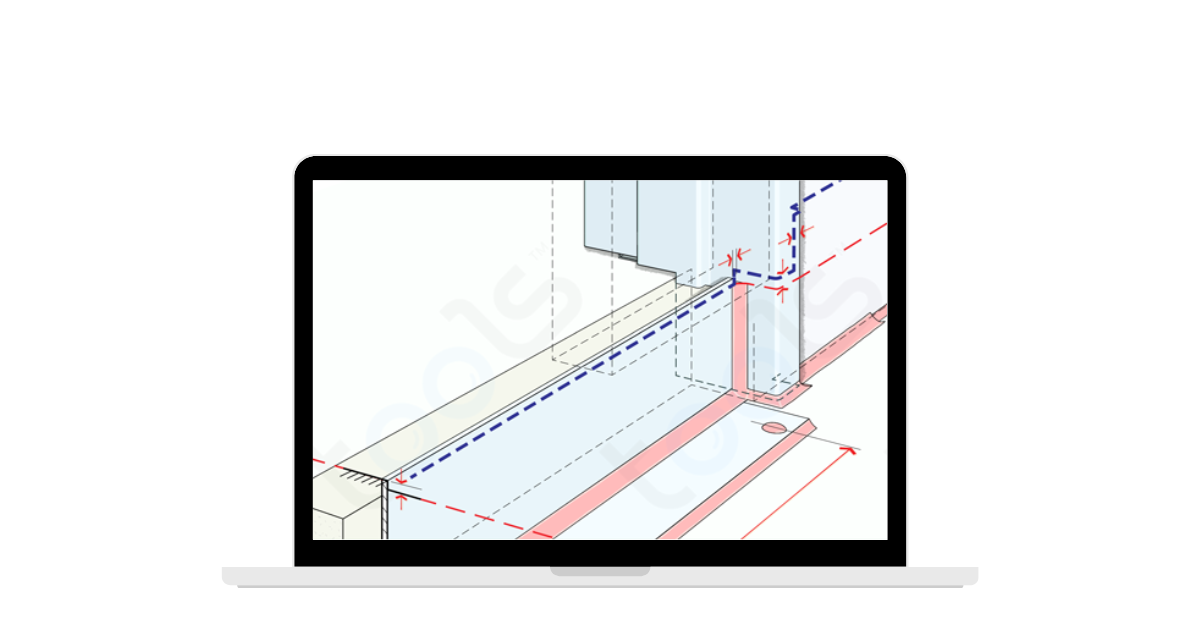

- locate the waterstop under centre of door

- installers, who are more expert than me, leave a 2mm gap both ends of the waterbar – they say this makes the vertical sealant joint stronger / more movement tolerant. I agree

- entomb the bases of jambs in the WPM – guess what? Steel is less likely to rust on the dry side of the membrane!

Steel jambs are often installed on bigger Class 2 – 9 projects. Our skill can stop them rusting or leaking where they are joined to the waterstop.

1 min read

1 min read  01 November 2024

01 November 2024